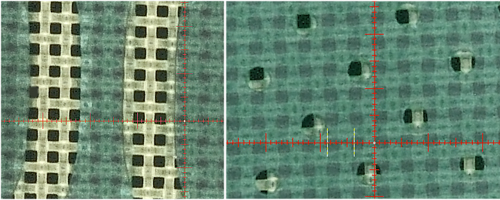

Dual Cure Emulsions provide a wider latitude of exposure to capture more of the image easier. Wash out and development of a dual cure is a bit easier than with a Pure Photopolymer emulsion. Dual Cure emulsion’s retain the emulsion’s properties even if under or over exposed slightly. Excellent resolution of details and sharp ink gasket’s provide a high degree of control in the print.

Dual Cure Emulsion:

SHELF LIFE: 4-6 WEEKS ONCE DIAZO IS MIXED INTO EMULSION

STORAGE: UP TO 80°F-26°C

Advance 20: High performance dual cure emulsion. Excellent resolution and edge quality. Exhibits low surface tack, excels at simulated process printing of fine halftones and fine trace circuitry printing.

TECHNICAL DATA SHEET | MSDS REQUEST

APPLICATIONS: GRAPHICS | ELECTRONICS | INDUSTRIAL

INKS: UV – SOLVENT

TECHNICAL DATA SHEET | MSDS REQUEST

APPLICATIONS: GRAPHICS | ELECTRONICS | INDUSTRIAL

INKS: UV – SOLVENT

Photocure PRO: Dual cure emulsions can help capture more tonal value due to their wider resolution. While slower exposing than a pure photopolymer emulsion, dual cure emulsions have a wider exposure latitude that can aid in capturing fine tonal values below 10% or fine details like copyright information. Photocure PRO images halftones and fine line details with ease. Resists UV and Solvent Inks well and can be hardened with MS or A&B Hardeners for use with water based graphic inks.

TECHNICAL DATA SHEET | MSDS REQUEST

APPLICATIONS: GRAPHICS | ELECTRONICS | APPAREL/TEXTILE

INKS: UV – SOLVENT – WATER BASE* – DISCHARGE*

Photocure PRO Heavy: This version of Photocure PRO has a higher viscosity for coating on lower mesh counts. Excellent image contrast and see through qualities of this emulsion promote easier set ups of the print while providing excellent exposure latitude.

TECHNICAL DATA SHEET | MSDS REQUEST

APPLICATIONS: GRAPHICS | ELECTRONICS | APPAREL/TEXTILE

INKS: UV – SOLVENT – WATER BASE* – DISCHARGE*

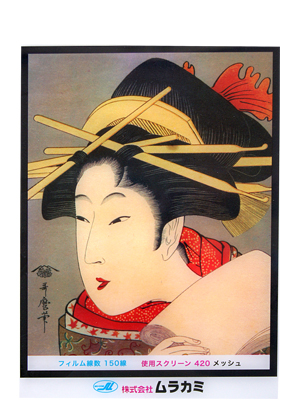

SP-9500 is Murakami’s premier dual cure emulsion. It is capable of printing many difficult hot solvent inks without breaking down. It has excellent resolution and is one of the most durable dual cure emulsions we make. Not intended for use with water based ink systems.

TECHNICAL DATA SHEET | MSDS REQUEST

APPLICATIONS: GRAPHICS | ELECTRONICS | INDUSTRIAL

INKS: UV – SOLVENT – HOT SOLVENT