Ff

Film: Term used for a clear film positive. Types of film include (in order of quality): Image Setter Film, Ink Jet Film and Vellum.

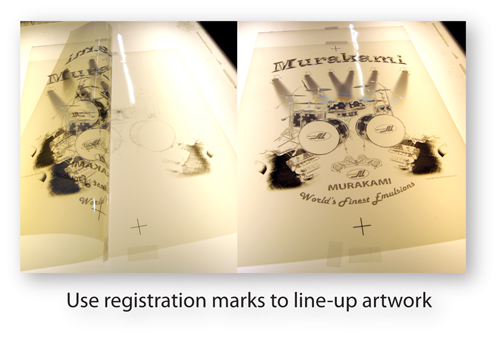

Film Positive: Image used for exposing a screen. Common types of media used for film in order of image resolution quality are image setter real film, ink jet film and vellum. Screen printing uses film positives as opposed to the opposite negative image. The purpose of the film positive is to cast a shadow on the film to prevent the emulsion from being exposed to light. This is the area of the screen that will wash out. The darker the black image the better the emulsion can be exposed. The image below shows 2 film positives with registration marks to line-up artwork.

Fish Eyes: A problem that occurs when a screen has not been degreased or dried properly. These appear as small circles or ribbons where the emulsion appears thinner than the surrounding area.

Flash Cure: Using a quartz or infra red heating element for a short amount of time to partially cure a print during the print process.

Flash Cure Unit: Positioned above the platen and used for the purpose of bringing a print to a partially cured state, an infrared heating element or quartz flash unit that is typically attached to a print head to partially cure a base plate or the entire image so a second print stroke can be applied to achieve desired opacity or to cure the ink prior the highlight white or black keyline print.

Flood Stroke: A squeegee stroke used to fill the ink well with ink prior to the squeegee stroke that clears the ink well or image area.

Fluorescent Ink: Extremely bright neon pigment colors in specialty inks.

Font: A particular size, weight and style of a typeface.

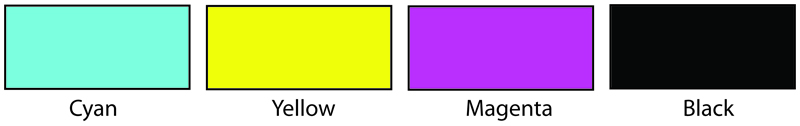

Four-Color Process: Printing utilizing the 4 ink colors : Cyan, Yellow, Magenta and Black to print the entire color spectrum.

Full Cure: Typically when a temperature of 320 degrees has been reached a state in which the plastisol ink film has completely fused. For discharge the entire image will be visible when it is cured with all colors as bright as they can achieve. For water base there are crock tests and chemical tests to determine if the print is colorfast.

Fusion: When plastisol ink has reached a full cure state and all cross linking of the plastisol is complete.